- New Inventory

- Used Inventory

- Promotions

- Finance

- Product Info

- Parts

- Service

- Why Us?

- Employment

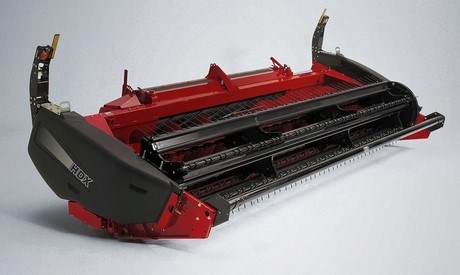

Sicklebar Headers

HDX182

Overview:

Quality cutting at uncompromised speed, the HDX182 Sicklebar Header handles heavy crop conditions.

Get A Quote

Fields with asterisks* are required. Please email our helpful staff with any questions or comments using the contact form.

Loan Calculator

Use the Loan Calculator to help you determine the financing and payment options that are best for you.

**The accuracy of this calculator and its applicability to your circumstances is not guaranteed. This information is provided for illustrative purposes only and does not constitute an application.

Send To A Friend

Fields with asterisks* are required. Your friend will receive an email that contains a reference to this page. Please send this email only to people you know who would be interested in this information.

Features

Cutterbar

Designed for a Cleaner Cut

The Case IH HDX series sicklebar headers are engineered to deliver a long life and a cleaner cut. Featuring bolt-on knife sections, hydraulic angle adjustments from 6 to 12 degrees below horizontal, a unique floating auger and easily adjustable skid shoes.

Conditioning Rolls

Built to Work in Heavy Crop Conditions

The HDX 2 Series Sicklebar Headers feature a conditioning system that is built to work in heavy crop conditions. Conditioning rolls crimp stems thoroughly for fast dry down. The roll pressure system uses a torsion bar, which allows conditioning rolls to automatically separate to clear slugs and the chevron pattern provides even windrow formation.

There are three options available: Rubber-on-Rubber, Steel-on-Steel, and Hi-Contact

Additional Options

Available Options on the WD5 Windrowers and HDX 2 Series

- In-cab control of reel speed

- In-cab control of windrow width

- Header gauge wheels

- Tall-crop lean bar kit

- Crop dividers

Specifications

| Cutting Width ft-in | 18ft 3in |

| Overall Width ft-in | 20ft 3in |

| Cutting Height Range - Minimum in | 1.2 |

| Cutting Height Range - Maximum in | 6.2 |

| Header Drive | Hydraulic |

| Gauge Wheels | Optional |

| Weight lb | 4370 |

| Single Or Double Knife | Timed dual counterstroking |

| Knife Drive | Open, dual, wobble |

| Min Knife Speed | 1810 |

| Max Knife Speed | 1810 |

| Sickle Stroke in | 3 |

| Min Cutter Bar Angle Range ° | 6 |

| Max Cutter Bar Angle Range ° | 12 |

| Number Of Bats | 5 |

| Reel Diameter in | 42 |

| Min Reel Speed, Mechanical rpm | 52 |

| Max Reel Speed, Mechanical rpm | 83 |

| Min Reel Speed, Hydraulic rpm | 0 |

| Max Reel Speed, Hydraulic rpm | 76 |

| Reel Drive Description | Var. sheave belt & chain / Hyd optional |

| Auger Description | Single, floating |

| Auger Diameter in | 20 |

| Auger Speed rpm | 287 |

| Auger Drive Type | Single, floating |

| Float Range in | 2 |

| Roll Length in | 102 |

| Roll Diameter in | 10.38 |

| Min Roll Speed rpm | 717 |

| Max Roll Speed rpm | 717 |

| Standard Roll Material | Rubber |

| Optional Roll Material | Steel or High-Contact urethane |

| Roll Surface Pattern | Chevron |

| Roll Pressure System | Torsion bar |

| Roll Adjustment Method | Hand Crank |

| Min Windrow/Swath Width in | 36 |

| Max Windrow/Swath Width in | 96 |